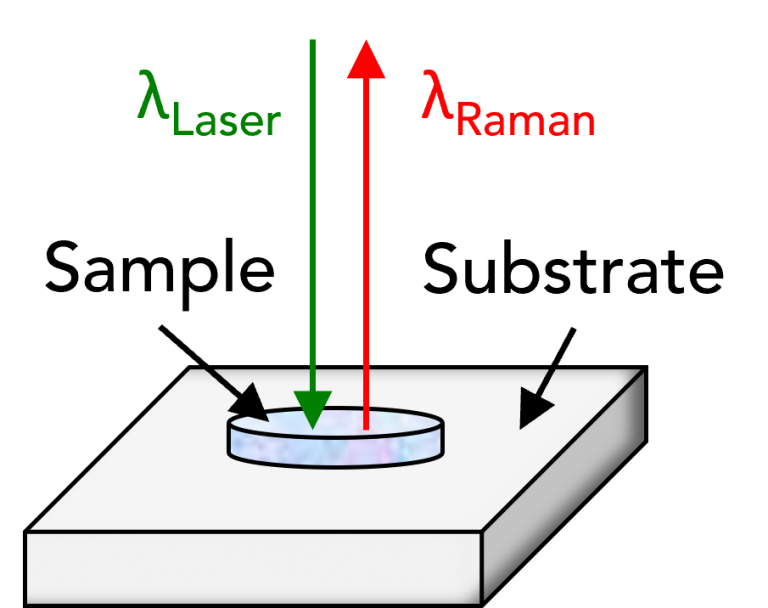

In Raman microscopy, there are a multitude of parameters that need to be considered to acquire high-quality data. One of these, often overlooked, is the substrate on which the sample is supported, Figure 1. Various substrate materials are available, and each can influence the measured Raman spectrum differently. It is essential to understand the Raman properties of the substrate when designing an experiment to ensure that its spectral output does not obscure information about the sample of interest.1 This Technical Note will discuss the properties of four different substrates (glass, quartz, calcium fluoride and stainless steel) commonly used for Raman microscopy.

Figure 1. The substrate in Raman microscopy.

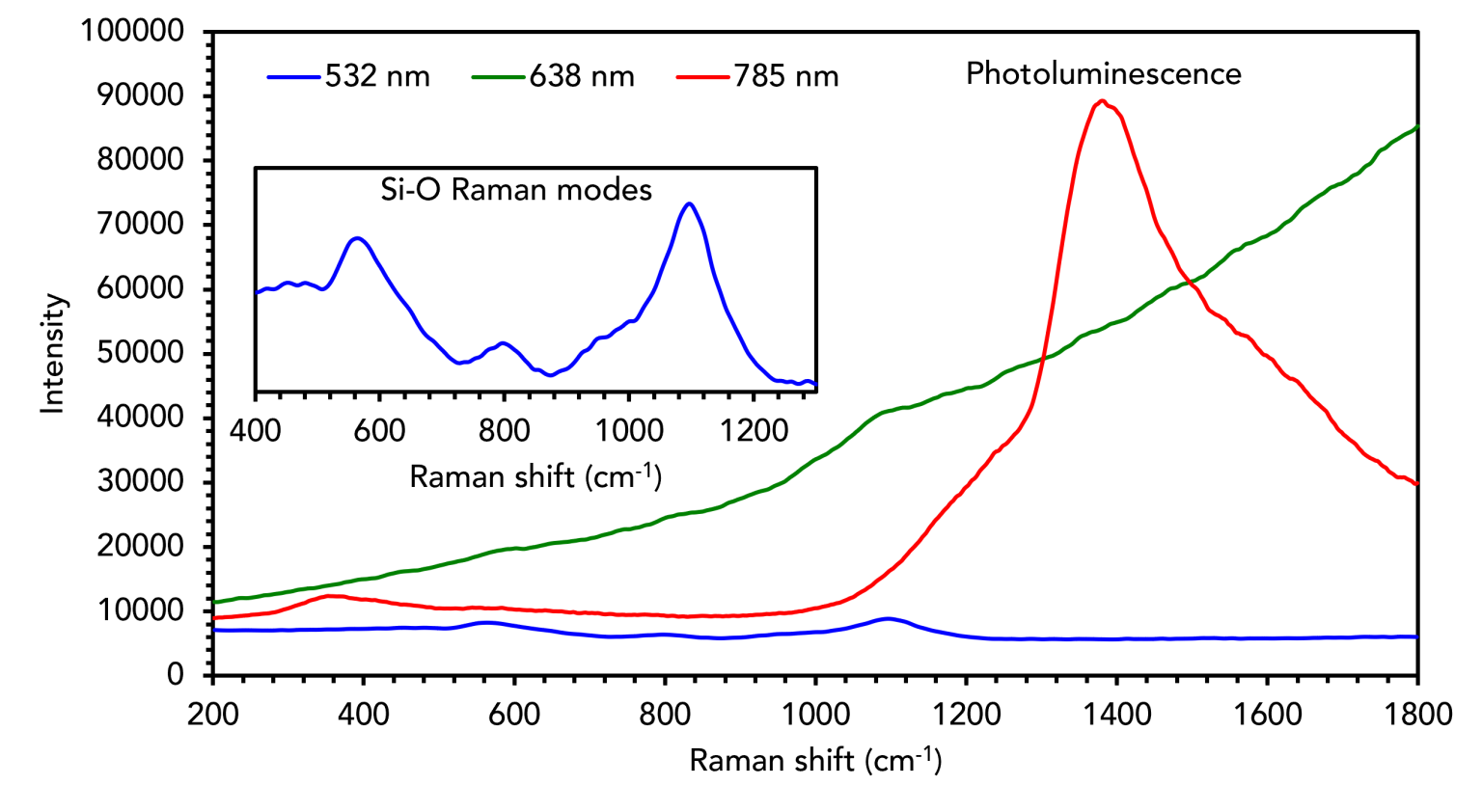

The most common and cost-effective substrate for microscopy is glass, which can be purchased relatively cheaply in large quantities. Being transparent, glass microscope slides can be used for both reflected and transmitted illumination widefield microscopy. However, a significant drawback of using glass for Raman microscopy is background photoluminescence (PL), which can obscure valuable spectral information when standard laser wavelengths are used.2 Figure 2 shows the contributions of glass in spectra acquired using three different lasers, spanning the visible and near-infrared (NIR) regions of the electromagnetic (EM) spectrum.

Figure 2. Raman analysis of glass using 532 nm, 638 nm, and 785 nm lasers.

When analysed with a 785 nm laser (red curve), the glass exhibits a strong PL band that peaks ca. 1400 cm-1. This can be observed when the overlying sample is transparent or when the sample is protected with a glass coverslip. At 638 nm (green curve), the glass spectrum shows a combination of Raman signatures and the rise of a PL band. There is no PL at 532 nm (blue curve), but the glass Raman spectrum is still relatively complex, and it contains multiple broad bands in the same spectral window as many potential functional groups of interest. These unwanted effects can be avoided by covering the glass with aluminium foil; however, this is unsuitable when low working distance objectives are used because it is difficult to secure it with the required level of precision. The best approach is to use an alternative material to glass.

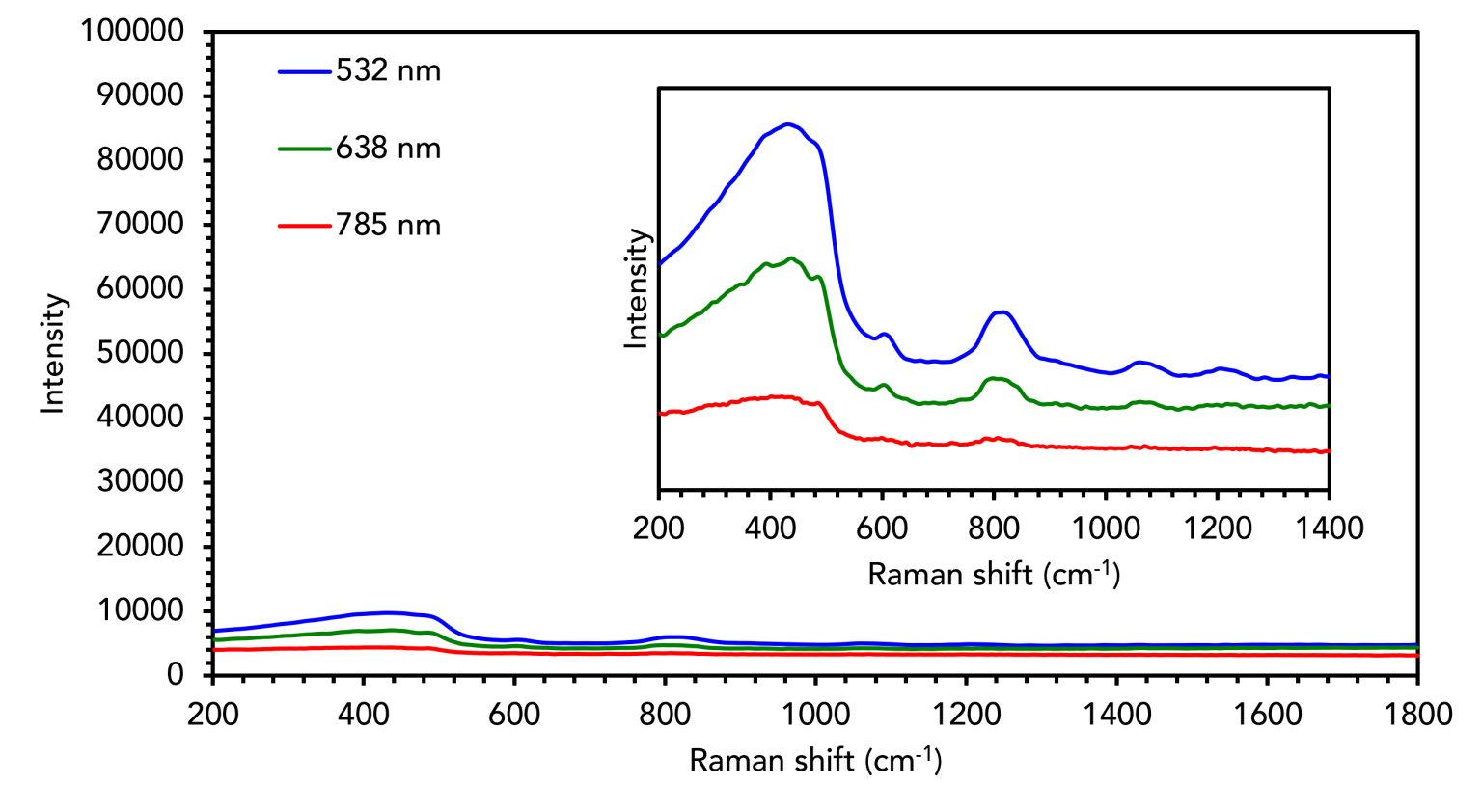

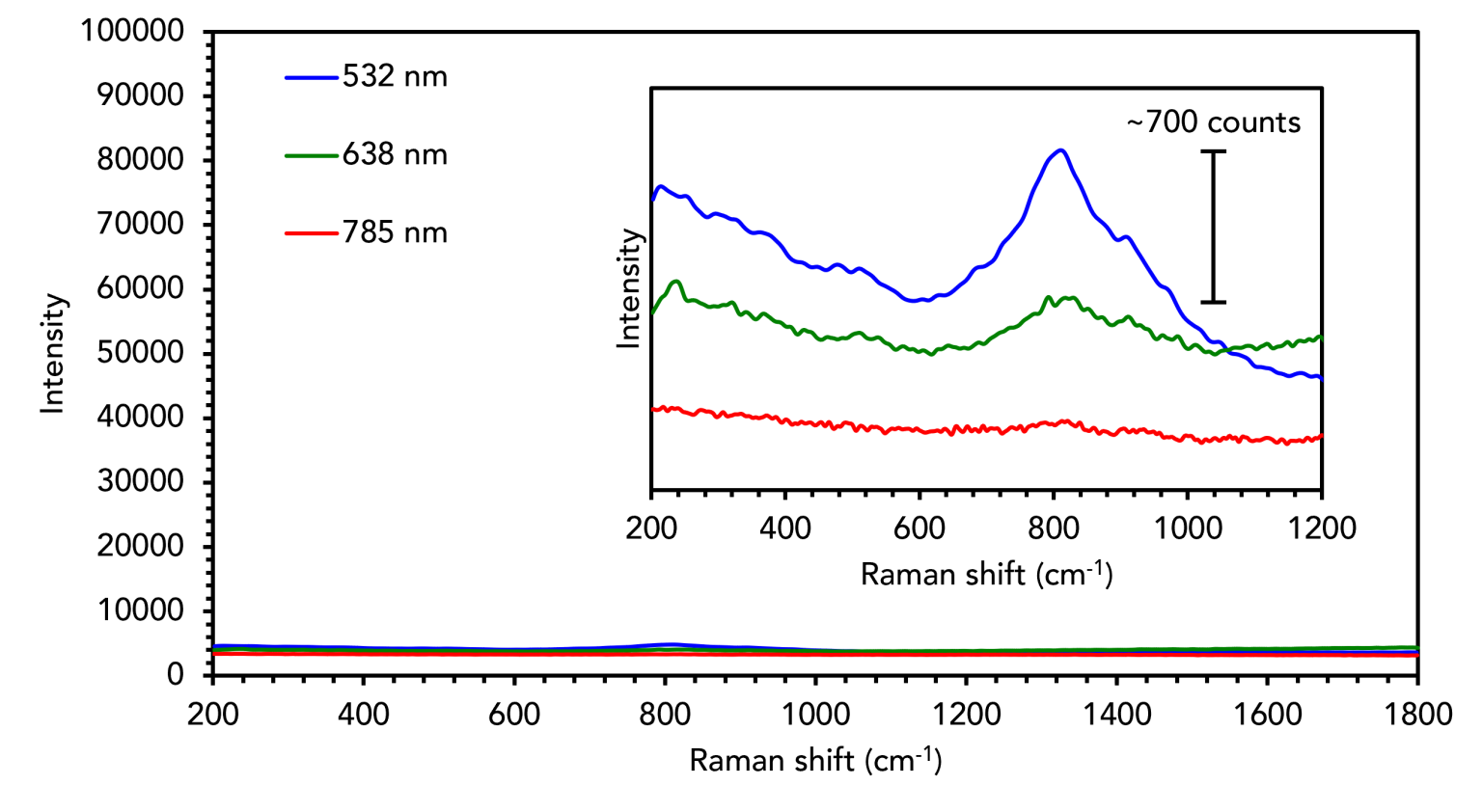

Fused quartz is an alternative transparent substrate that can be used for Raman microscopy. The spectral output of quartz is less variable than glass when probed with different laser wavelengths. Figure 3 shows that quartz does not exhibit PL, a significant advantage over glass. The larger spectral plot is on the same scale as the above glass spectra, and the inset plot shows the vibrational signatures of the quartz in greater detail. The Raman spectrum is still complex compared to other available substrates, but the most prominent band is in a low wavenumber region that is less likely to overlap with vibrational modes of interest. Quartz is the substrate of choice in high-temperature Raman applications because it is extremely heat-resistant.

Figure 3. Raman analysis of fused quartz using 532 nm, 638 nm, and 785 nm lasers.

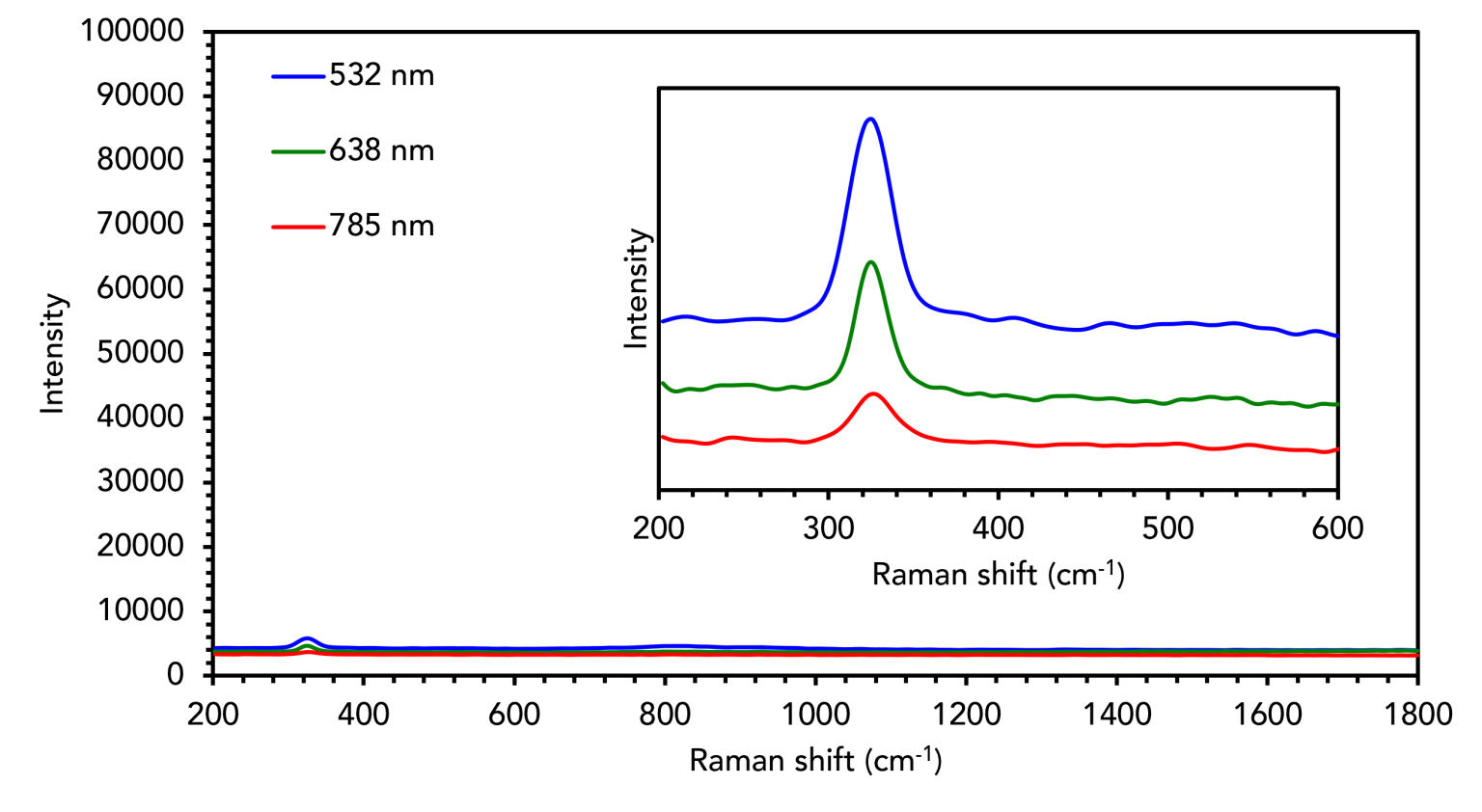

Calcium fluoride (CaF2) is another transparent material often considered the “gold standard” of Raman microscopy substrates. CaF2 has optical properties that are more favourable than glass and quartz for most Raman microscopy applications. To show this, the spectra of a CaF2 disk obtained with different wavelengths are plotted in Figure 4. CaF2 exhibits no PL, similar to quartz. The advantage of CaF2 is that it only has one narrow Raman band, ca. 330 cm-1, a frequency range in which most functional groups will not vibrate. This band is less likely to obscure sample features than the more complex Raman spectra of glass and quartz.

Figure 4. Raman analysis of calcium fluoride using 532 nm, 638 nm, and 785 nm lasers.

Stainless steel slides are a non-transparent alternative to the previously discussed substrates with minimal background and no Raman spectral signatures. As shown in Figure 5, stainless steel shows less Raman signal than any of the aforementioned materials and negligible background emissions, making it an excellent substrate for Raman microscopy applications.

Figure 5. Raman analysis of stainless steel using 532 nm, 638 nm, and 785 nm lasers.

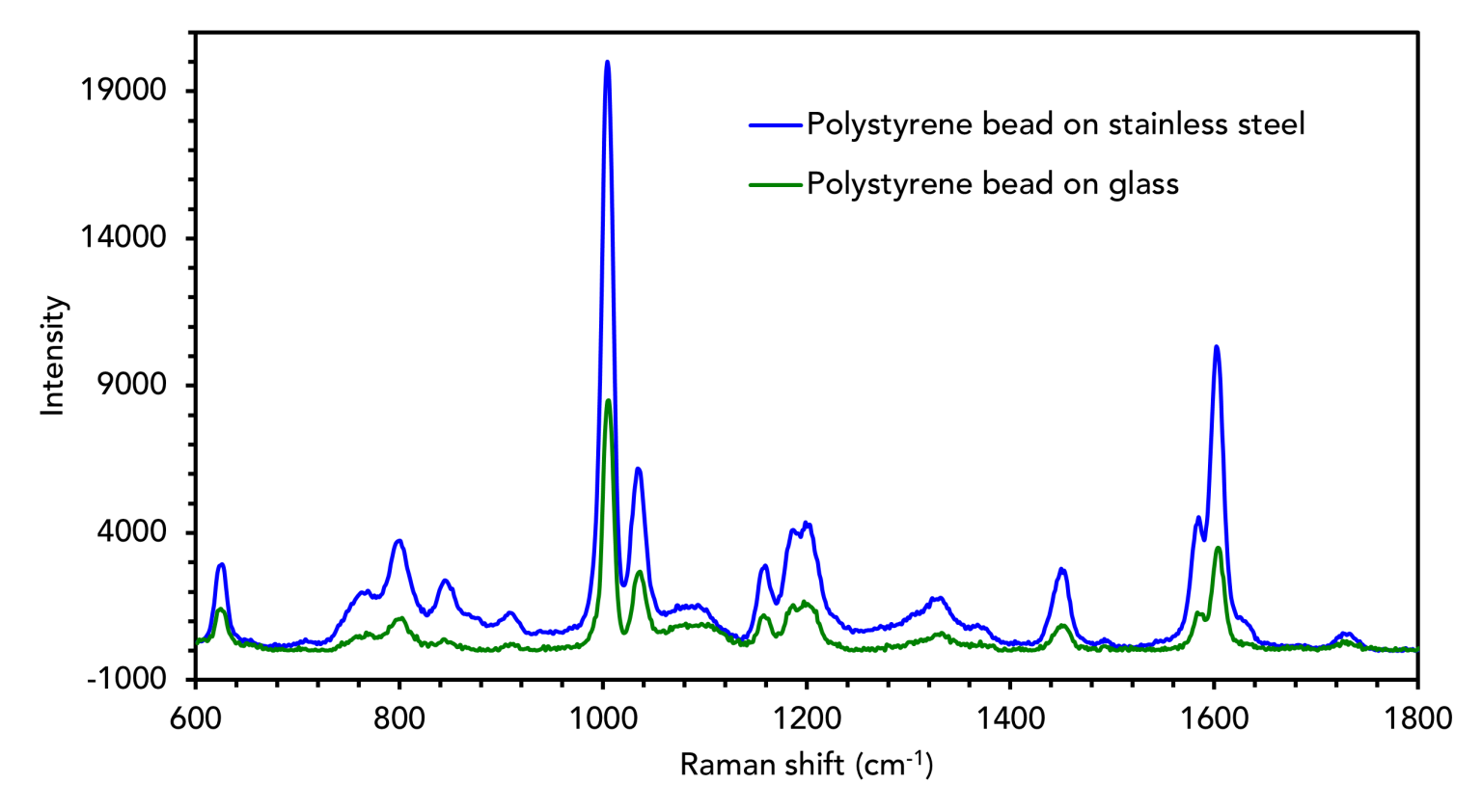

Stainless steel is not transparent to white light, and sample viewing is therefore limited to reflected illumination microscopy. Stainless steel can enhance the Raman intensity over alternative transparent materials because the reflectivity of the metal surface allows for double-pass of the laser beam through the sample.3 To demonstrate this, individual 3 μm polystyrene beads were analysed on glass and stainless steel, Figure 6. With the same laser and scatter path conditions, there is a significant improvement in the Raman intensity detected when the bead is on the steel substrate (blue) versus the glass (green).

Figure 6. Raman analysis of polystyrene beads on stainless steel and glass substrates.

In this Technical Note, we have discussed the effects of various sample substrates, such as glass, used for Raman microscopy, summarised in Table 1. It should be noted that quartz, calcium fluoride, and stainless steel are more expensive than glass, but they can also all be washed, sterilised, and reused. By understanding the properties of different substrates, it is easy to select the correct one and ensure that the spectral output of an experiment is exclusively from the sample of interest.

Table 1. Summary of the sample substrate materials discussed above.

| Material | PL | Raman | Microscopy Modes |

|---|---|---|---|

| Glass | Yes | Multiple broad peaks | Reflected and transmitted illumination |

| Quartz | No | Broad peaks in low wavenumber region | Reflected and transmitted illumination, high-temperature cells |

| Calcium fluoride | No | One narrow peak in low wavenumber region | Reflected and transmitted illumination |

| Stainless steel | No | No | Reflected illumination only, intensity enhancement due to laser double-pass |